Are you facing trouble with your Harbor Freight 800 Watt Generator? Are you looking for a reliable and affordable repair solution? If yes, then this article on Harbor Freight 800 Watt Generator Repair is just the thing you need. In this article, we will provide you with some useful tips and tricks to help you fix your power source with ease. So, read on to learn more!

Type of Harbor Freight Generators

| Model | Power Rating |

|---|---|

| Predator 3500 Watt Super Quiet Inverter Generator | 3500 Watts |

| Predator 6500 Watt Max Starting Extra Long Life Gas Generator | 6500 Watts |

| Predator 4000 Watt Max Starting Gas Powered Generator | 4000 Watts |

| Predator 8750 Watt Max Starting Extra Long Life Gas Generator | 8750 Watts |

| 800 Watt Super Quiet Inverter Generator | 800 Watts |

| Storm Cat 800 Watt Portable Generator | 800 Watts |

| Storm Cat 900 Watt Portable Generator | 900 Watts |

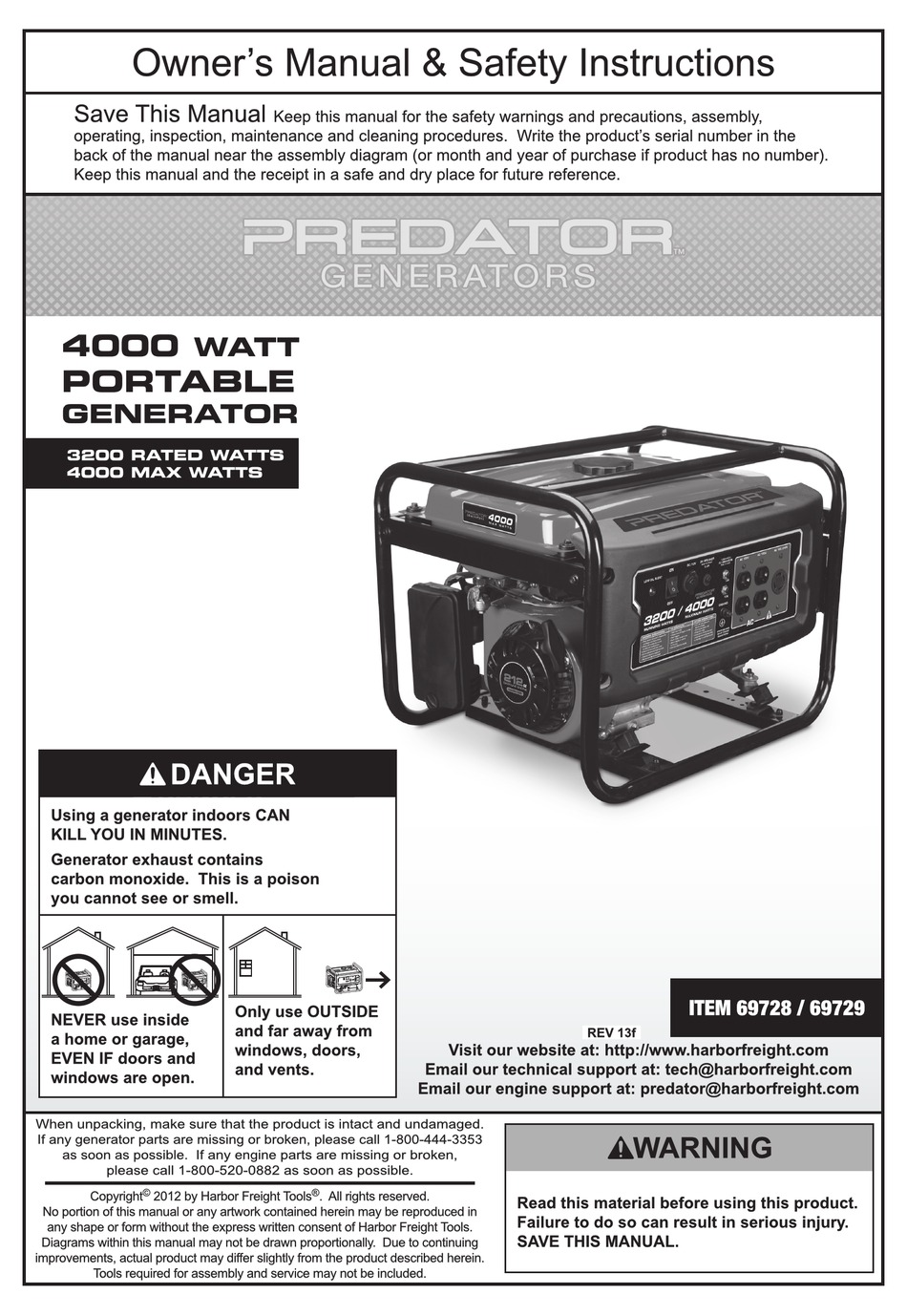

Harbor Freight offers a wide selection of generators, ranging from 800 Watts to 8750 Watts. Popular models include the Predator 3500 Watt Super Quiet Inverter Generator, Predator 6500 Watt Max Starting Extra Long Life Gas Generator, Predator 4000 Watt Max Starting Gas Powered Generator, Predator 8750 Watt Max Starting Extra Long Life Gas Generator, 800 Watt Super Quiet Inverter Generator, Storm Cat 800 Watt Portable Generator, and Storm Cat 900 Watt Portable Generator.

Common Problems of Harbor Freight Generators

- Inadequate fuel supply – Your generator needs a steady supply of fuel to run properly. If your fuel supply is inadequate, the generator will not be able to sustain a consistent output.

- Clogged air filter – The air filter ensures that fresh air is supplied to the engine for combustion. If the air filter is clogged, the generator will not be able to maintain a consistent output.

- Worn spark plug – A spark plug is responsible for igniting the fuel-air mixture in the engine. If the spark plug is worn or damaged, the generator will not be able to generate an adequate spark to ignite the fuel-air mixture.

- Faulty carburetor – The carburetor is responsible for mixing the fuel and air in the proper ratio for combustion. If the carburetor is not functioning properly, the generator will not be able to generate a consistent output.

- Dirty or clogged fuel tank – The fuel tank needs to be clean and free of debris in order for the generator to run properly. If the fuel tank is dirty or clogged, the generator will not be able to generate a consistent output.

- Faulty voltage regulator – The voltage regulator is responsible for maintaining a consistent voltage output from the generator. If the voltage regulator is not functioning properly, the generator will not be able to maintain a consistent output.

- Loose or damaged wiring – Wiring is responsible for providing power to the various components of the generator. If the wiring is loose or damaged, the generator will not be able to generate a consistent output.

- Faulty starter motor – The starter motor is responsible for turning the engine over and starting it up. If the starter motor is not functioning properly, the generator will not be able to start up.

Safety Tips for Harbor Freight Generator Repair

| Safety Tip | Description |

|---|---|

| Wear Safety Gear | Always wear safety glasses, gloves, and a dust mask when working on a generator. |

| Read the Manual | Familiarize yourself with the generator and read the manual before performing any repairs. |

| Unplug the Generator | Before performing any repair, make sure to unplug the generator from the power source. |

| Check the Fuel Lines | Check the fuel lines for any cracks, leakage, or blockages before starting the generator. |

| Keep Children and Pets Away | Keep children and pets away from the generator to avoid any accidents. |

| Check the Oil Level | Check the oil level before starting the generator to avoid any engine damage. |

| Take Breaks | Take breaks while working and avoid working for long periods of time. |

Diagnosing Harbor Freight Generator Problems

The Harbor Freight 800 Watt Generator is a popular and reliable model of generator, but it can still have issues. Common causes of generator failure include an insufficient fuel supply, a malfunctioning carburetor, or a faulty spark plug. Here are some tips for diagnosing problems with your Harbor Freight Generator:

| Problem | Diagnosis | Solution |

|---|---|---|

| Engine won’t start | Check fuel supply, carburetor, and spark plug | Replace fuel, clean carburetor, and replace spark plug |

| Engine runs rough | Check fuel supply, carburetor, and spark plug | Replace fuel, clean carburetor, and replace spark plug |

| Engine runs too hot | Check fuel supply, air filter, and cooling system | Replace fuel, clean air filter, and check cooling system |

| Engine runs but produces no power | Check generator head, voltage regulator, and alternator | Replace generator head, voltage regulator, and alternator |

If any of these solutions do not solve the issue, it is best to consult a professional for further diagnosis and repair.

Fixing Common Harbor Freight Generator Problems

- Carburetor Problems: A dirty or faulty carburetor can cause the engine to run rough and lose power. To fix this, first clean the carburetor using a carburetor cleaning spray and a small brush. After that, check the fuel lines and filter for any blockages and replace if necessary.

- Spark Plug Problems: Faulty spark plugs can cause the engine to misfire or fail to start. To fix this, check the spark plug for any signs of wear and tear and replace it if needed.

- Air Filter Problems: A clogged air filter can reduce the engine’s performance and fuel efficiency. To fix this, replace the air filter with a new one.

- Fuel Tank Problems: A faulty fuel tank can prevent the fuel from reaching the engine. To fix this, check the fuel tank for any cracks or leaks and repair or replace it if necessary.

- Ignition System Problems: A faulty ignition system can cause the engine to fail to start. To fix this, check the ignition system for any signs of wear and tear and replace any faulty components.

- Voltage Regulator Problems: A faulty voltage regulator can cause the generator to produce too much or too little voltage. To fix this, check the voltage regulator for any signs of wear and tear and replace it if necessary.

Troubleshooting Harbor Freight Generator Issues

The Harbor Freight 800 watt generator is a reliable source of electricity for many construction and home projects. However, from time to time, it may need some troubleshooting. The following steps will help you diagnose and fix the issues you may encounter with your Harbor Freight generator.

First, check to make sure the generator is getting power. Check the power cord to make sure it is properly connected to the generator and the outlet. If the generator is plugged in, then inspect the electrical circuit breaker to ensure it has not tripped.

If the generator is getting power, then turn it on and check for any fuel-related issues. Make sure the gas tank is full and the fuel lines are connected properly. If the fuel lines are clogged, then you may need to replace them. Also, check the air filter to ensure it isn’t clogged and is clean. If the air filter is dirty, then replace it.

If the generator is still having issues, then inspect the spark plug. Make sure it is in good condition and isn’t corroded. If it is damaged, then replace the spark plug.

Finally, if the generator is still not working, then inspect the carburetor. Check to see if the fuel and air mixture is correct and the carburetor is clean. If the carburetor is dirty, then it needs to be cleaned before the generator will work properly.

Following these steps should help you diagnose and fix any issues you may have with your Harbor Freight 800 watt generator. If the issue persists, then contact an authorized service center for further assistance.

Replacing and Repairing Parts of Harbor Freight Generators

| Part | Replacement | Repair |

|---|---|---|

| Fuel Tank | Replace with an original replacement part | Check for leaks and corrosion |

| Air Filter | Replace with an original replacement part | Clean and replace if necessary |

| Spark Plug | Replace with an original replacement part | Check condition and gap |

| Carburetor | Replace with an original replacement part | Clean and adjust the float |

| Fuel Lines | Replace with an original replacement part | Check for leaks and damage |

| Oil Filter | Replace with an original replacement part | Clean and replace if necessary |

| Starter Cord | Replace with an original replacement part | Check for wear and tear |

| Recoil Starter | Replace with an original replacement part | Check for damage and wear |

| Engine | Replace with an original replacement part | Check for worn parts and valves |

| Ignition Switch | Replace with an original replacement part | Check for loose wires and corrosion |

| Battery | Replace with an original replacement part | Recharge and replace if necessary |

When repairing a Harbor Freight generator, it is important to replace and repair parts with original replacement parts. This will ensure that the generator is running at its best and will last longer. Common parts that need to be replaced or repaired include the fuel tank, air filter, spark plug, carburetor, fuel lines, oil filter, starter cord, recoil starter, engine, ignition switch, and battery. It is important to check each part for leaks, corrosion, wear, and damage. Additionally, the battery needs to be recharged and the float needs to be adjusted on the carburetor. If any of these parts are not working properly, it is important to replace or repair them in order to keep the generator running efficiently.

Maintenance Tips for Harbor Freight Generators

- Check the oil level regularly. Change the oil and oil filter every 100 hours of operation.

- Change the air filter at least once a year.

- Clean the spark plug and set the gap according to the manufacturer’s recommendations.

- Clean the generator’s fuel tank and fuel lines.

- Check all electrical connections for tightness and corrosion.

- Check the generator’s exhaust system for leaks.

- Check the generator’s starter system for proper operation.

- Check the generator’s voltage regulator for proper operation.

- Check the generator’s cooling system for proper operation.

- Check the generator’s alternator for proper operation.

Frequently Asked Questions

How do I repair a Harbor Freight 800 watt generator?

To repair a Harbor Freight 800 watt generator, first disconnect it from all sources of power. Then, check the fuel lines for any blockages or leaks and replace any necessary components. Also check the air filter for debris buildup and replace if necessary. Finally, inspect the spark plugs and carburetor for any signs of damage and replace if necessary. If the generator still does not start, take it to a qualified technician for further inspection and repair.

What are the reviews of the Harbor Freight 800 watt generator?

The Harbor Freight 800 watt generator has generally received positive reviews for its affordability, portability, and ease of use. Many users have praised the generator for its reliable performance and quiet operation. Some minor complaints have been raised about the product’s lack of power and short run time. Overall, the Harbor Freight 800 watt generator is a good choice for those looking for a reliable, budget-friendly generator.

Is it easy to repair a Harbor Freight 800 watt generator?

Repairing a Harbor Freight 800 watt generator is not overly difficult, but it may require some technical knowledge and skill. The best way to approach the repair is to consult the user manual and follow the instructions provided. If the repair requires parts that are not included in the manual, it may be necessary to contact a technician or a service center for assistance. In addition, it is important to use the correct tools and safety equipment when attempting to repair the generator.

Are there any special tools needed for Harbor Freight 800 watt generator repair?

No, you don’t need any special tools to repair a Harbor Freight 800 watt generator. Regular tools such as pliers, wrenches, and screwdrivers will do the job. You may need to purchase a few fuel line fittings and connectors for the job, but apart from that, no special tools are needed.

Are there any specific instructions for Harbor Freight 800 watt generator repair?

No, there are not any specific instructions for Harbor Freight 800 watt generator repair. As with other small engine repairs, the recommended approach is to first troubleshoot the issue, then refer to the manufacturer’s technical manual for guidance on specific repair procedures. If the manual is not available, it is possible to obtain a replacement manual online or by contacting the manufacturer directly. Additionally, it is important to be aware of safety precautions when performing any generator repair.

Conclusion

The Harbor Freight 800 Watt Generator is a dependable and affordable power source. With a few simple repairs, it can be running in no time. By replacing the spark plug, cleaning the air filter, and checking the oil level, your generator should be good to go. With regular maintenance and the right tools, you can keep your Harbor Freight 800 Watt Generator running for years to come.